You need to design your completions for multi-well pads, generate a perf plan, a pump schedule, and a completion procedure document for each one. The only viable option is to use a geometric design and a single pump schedule. Like 95% of the completion engineers, you probably take the Excel spreadsheet from your last well, update the hardlines and toe configuration to get your completable lateral. Then you apply your standard design and pump schedule. Then you probably spend a couple of hours doing quality control to avoid any copy-paste errors and you generate the operational documents (perforation plan, pump schedule, and completion procedure document). Sound familiar?

Maybe you could tune your completion design, but you don’t have time for that, you need to get those wells on production as soon as possible.

Engineers who use DeepData cut their typical design time by more than 90% and get better production results!

"*" indicates required fields

Designing a Well (Physical Designs & Pump Schedules)

Design your completion by simply dragging your custom physical designs and pump schedules onto the directional survey. In seconds, you have a fully designed well.

Moving Perf Clusters to Target Rock Properties

Optimize your design by dragging perf clusters (dotted lines) and plugs (black lines) to the right position based on any combination of rock properties.

Design Efficiency

DeepData automates everything. It uses your company’s templates for defining the completable lateral (buffers, max DLS, min Inclination, etc.). Then you simply drag physical design(s) and pump schedules onto the diagram of your directional survey and it lays them out for you. Then it automatically generates the operational documents…it only takes minutes to design your completion and generate the associated documents.

Design Optimization

There are a number of ways to optimize your completion designs that will make significant improvements in well economics by both reducing costs and increasing production. All of these optimizations are driven by designing your completion based on the rock along your lateral. Here are just a few examples:

GROUPING SIMILAR ROCK

Chose any curve (.LAS file) and DeepData will shift your clusters to target the optimal locations to hit the best rock. It doesn’t matter whether you use Gamma Ray, Drill bit geomechanics, cutting analysis, anything. You set the constraints and the target and DeepData automes the rest.

ROCK GRADING

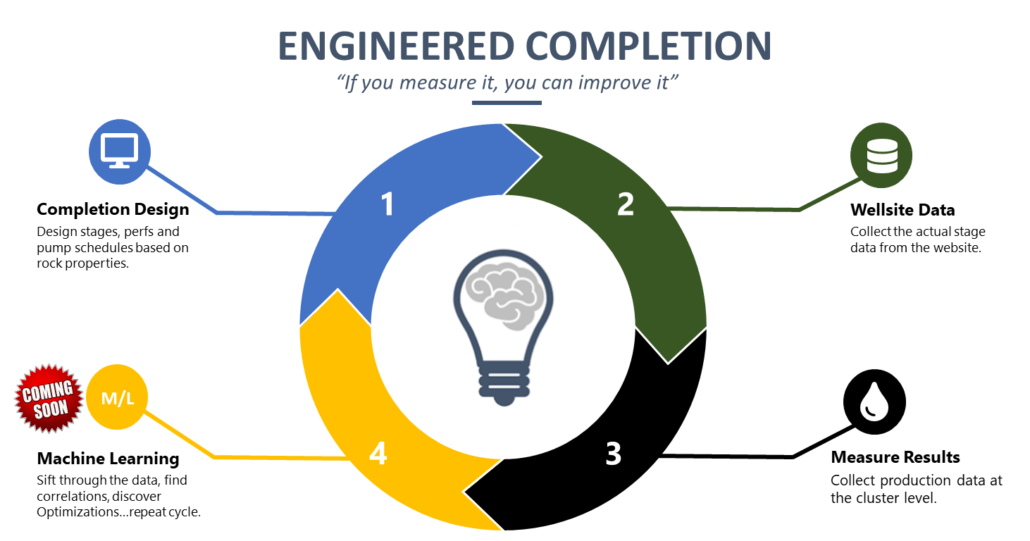

Machine Learning enables us to correlate rock properties, physical design, treatment and results. Running all of this data through machine learning will soon drive continuous optimization.

DeepData provides the option to automatically design your stages to group similar rock. This enables a more uniform frac. For example, if a stage combines both brittle and ductile rock, the ductile rock won’t fracture (without expensive diverter), thereby reducing the efficiency of your stimulation.

CLUSTER PLACEMENT

DeepData’s patent pending process enables you to define rock quality from any combination of data. Then you can apply physical designs and pump schedules accordingly. For example you might define rocks types as: small, medium and large. When you are out of zone or in poor rock, you might reduce proppant loads by 30%, while boosting it 20% in high-quality rock. This alone can boost production while significantly reducing costs. You can apply allsorts of strategies like this, being as aggressive or conservative as you want to be.

MACHINE LEARNING - COMING SOON

The upstream E&P business is evolving along the same trajectory as automobiles. Initially all cars were custom built by hand. Then Henry Ford introduced the era of mass manufacturing, where every car was the exact same. You may have heard Henry Ford’s famous line: “Any customer can have a car painted any color that he wants so long as it is black.” Then the car business transitioned to mass customization, where each car could be tailored to customer demands. The upstream E&P business is currently in the mass manufacturing mode, with geometric completion design. DeepData is a tool that ushers you into the next phase, mass customization, where every well is optimized based on the rock properties of that unique well.

“ Using analytics to double output, thus cutting oil costs in half, means that shale break-even costs would drop to $5 per barrel–$25 per barrel. America’s shale fields would then be competitive in volume and in price with Saudi Arabia’s vaunted ultralow-cost oil fields.”

Return on Investment (ROI)

DeepData’s model is simple: Operators pay per well for a 5-year license for the Completion Design module. It includes as many users as you want at no charge. You can even invite your service providers to load data for you. This fee goes on the AFE, so the cost is shared by your NonOps.

This cost is quickly dwarfed by your ROI. The design efficiency alone pays for the license. When you consider that just a few small design wins, such as skipping out of zone segments, reducing proppant in sections with poor rock, and more the return is huge. These are the low-hanging fruit and they alone can give you a 1,500% ROI on your first well. That only addresses the cost side of the equation. Grouping similar rock for more uniform fractures, targeting perf clusters in better rock, these simple and automated actions can result in a huge ROI.

Zero-Risk Guarantee